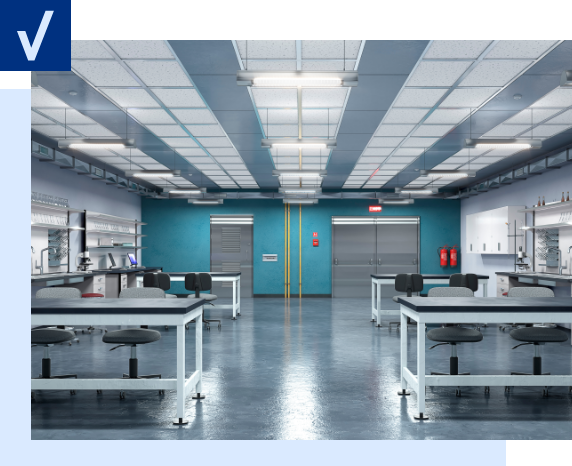

Life Sciences

Cleaning, an Essential Element

Cleaning is an essential element of contamination control. That is why Harvard has established Standard Operating Procedures for Cleaning & Maintenance of Controlled Environments. Our SOP details cleaning regulations recommended as a minimum for the successful operation of a clean environment in compliance with Federal and ISO Standards, within their specified classifications, from class 1 (M1.5) to 100,000 (M6.5) or ISO 14644-1: Class 3 – Class 9. Our experienced team can help to develop an effective service program, or customize our staff training and work instructions to align with your established protocols and procedures.

Contamination Prevention

To reduce a cleanroom’s risks of contamination, it is essential that an effective preventative cleaning program be implemented and maintained consistently throughout the life of the cleanroom or controlled environment. Harvard’s techniques are proven to remove dirt, dust, and other contaminants from your cleanroom or controlled area, while preventing any contamination in the process.

Qualified Staff

All personnel performing housekeeping maintenance within controlled environments have received specialized training to include:

- Cleanroom techniques and procedures

- Tasks and frequencies for the specific cleanroom class

- Products utilized per client specifications

- Contamination control

- Proper gowning

Benefits

- Standard Operating & Maintenance Procedures for Laboratory & Controlled Environments

- Federal and ISO Standards

- Contamination Control

- Customized Work Plan

- Customized Statement of Work, Reporting, and Invoicing

- Specialized Job Cards